Product description

The JN BM1 OMP BMP Cycloidal Hydraulic Motor is a top-performing hydraulic motor that offers a range of benefits and features. Its unique cycloidal cam mechanism ensures high efficiency, low noise level, and good starting capability, making it ideal for a wide range of applications. Contact a trusted hydraulic motor supplier today to learn more about the benefits of the OMP BMP Cycloidal Hydraulic Motor. It can replace Danish Danfoss OMP products.

JN BM1 OMP BMP cycloidal hydraulic motors are used in a wide range of applications.The OMP BMP cycloidal hydraulic motor has always been a very important component in the field of industrial manufacturing. Due to its excellent performance and wide range of applications, it has become one of the key components of all types of machines and equipment. The following are the specific uses of BMP cycloidal hydraulic motors in various application areas.

1. Construction machinery OMP BMP cycloidal hydraulic motor is one of the key components of large construction machinery such as excavators, forklifts, and bulldozers. In these large machines, hydraulic motors are responsible for providing power, which controls the movement of the machinery and performs various tasks. The OMP BMP cycloidal hydraulic motor has the characteristics of high torque, low-speed cruise, etc., and can withstand high pressure and long working time in construction machinery.

2. Petroleum equipment OMP BMP cycloidal hydraulic motors are also widely used in the petroleum equipment industry, such as drilling rigs, oil pumps, etc. In the petroleum equipment industry, the working environment of hydraulic motors is relatively harsh, and it needs to have strong corrosion resistance and high temperature resistance. The OMP BMP cycloidal hydraulic motor has a precise structural design and a high degree of reliability, which can adapt to the harsh operating environment.

3. Agricultural machinery OMP BMP cycloidal hydraulic motors are also widely used in the agricultural machinery industry. It is used to drive the movement of equipment such as harvesters, tractors, and planters. In these mechanical equipment, hydraulic motors need to have high timeliness and low energy consumption to meet the requirements of long-term and efficient operation of agricultural machinery.

4. Shipbuilding OMP BMP cycloidal hydraulic motors are also widely used in the marine industry. On ships, hydraulic motors are an important part of systems such as servos, pumps, and oil pipes.OMP BMP hydraulic motors are one of the most popular choices for shipbuilders due to their high torque, high efficiency and reliability.

The OMP BMP cycloid hydraulic motor is an excellent choice for a wide range of hydraulic applications. Its high efficiency, durability, and ease of maintenance make it a reliable and cost-effective option for heavy duty systems. Whether you are building a construction crane, a dump truck, or any other type of hydraulic system, the OMP BMP motor is sure to provide the performance and reliability that you need.

OMP BMP Orbit hydraulic motor is a multi-functional hydraulic equipment, which can be widely used in various heavy machinery and industrial equipment, such as drilling rigs, loaders, excavators, agricultural machinery and industrial automation equipment, etc. As a high-performance hydraulic component, the OMP BMP cycloidal hydraulic motor has the following main applications in mechanical transmission systems.

1. Strong transmission capacity: The OMP BMP cycloidal hydraulic motor has a wide range of speeds, from large torque at low speed to high speed at high speed, which can meet the needs of the mechanical transmission system, and can withstand strong load capacity, so that it can work in dangerous environments.

2. Stable and reliable: The OMP BMP cycloidal hydraulic motor adopts a reliable sealing structure, which can effectively prevent liquid leakage and oil and gas mixing. At the same time, all its components are manufactured and tested with high quality, which guarantees the stability and reliability of its work.

3. Easy operation: The operation of the OMP BMP cycloidal hydraulic motor is simple, and only one hydraulic control valve is needed to realize forward, backward and stop operations. In addition, it enables the control and regulation of mechanical systems.

4. High efficiency and energy saving: The OMP BMP cycloidal hydraulic motor has extremely high conversion efficiency and energy recovery capacity, which can effectively reduce energy loss in the working process, thereby saving energy.

Overall, the OMP BMP cycloidal hydraulic motor is an advanced hydraulic component that has a wide range of applications in mechanical transmission systems. Whether it is in mines, factories or other industries, it has a wide range of application prospects. Therefore, the development and application of OMP BMP cycloidal hydraulic motor will become more and more extensive, and continue to promote the development of the machinery industry.

With low speed high torque , OMP BMP Orbit Hydraulic Motor adopts the latest design of fixed rotor pair with output shaft and linkage shaft, thus greatly reducing friction and improving efficiency.

Hydraulic motors are essential components of hydraulic systems, which are used in a wide range of industries. These motors convert hydraulic energy into mechanical energy, providing a powerful and efficient source of rotational force. Among different types of hydraulic motors, the cycloidal hydraulic motor, also known as a gerotor motor or a cycloid motor, is one of the most popular choices for its unique design and performance features. In this article, we will introduce the product features of the cycloidal hydraulic motor, also known as a fixed displacement hydraulic motor or a wobble motor.

1. High efficiency

The cycloidal hydraulic motor boasts a high efficiency because of its unique design. The motor utilizes a cycloid cam, a star-shaped rotor, and an eccentric bearing to create a rolling motion, which generates high torque at low speeds and high speeds. The motor has fewer moving parts, which reduces energy loss and improves overall efficiency.

2. High starting torque

The cycloidal hydraulic motor features a high starting torque, making it ideal for heavy-duty applications. Because of its unique design and construction, the motor is able to deliver high torque from the start, making it easier to move loads and overcome resistance.

3. Smooth, quiet operation

The cycloidal hydraulic motor offers a smooth, quiet operation due to its low noise and vibration levels. Its rolling motion minimizes stress and strain, which reduces noise and vibration while increasing durability and reliability. As a result, the motor can be used in a wide range of applications, including in machinery and equipment that require low-noise operation.

4. Compact, lightweight design

The cycloidal hydraulic motor has a Compact, lightweight design, which makes it easy to install and use in tight spaces. Its small size and low weight make it ideal for use in mobile machinery, such as construction vehicles and agricultural equipment, where weight and space are at a premium.

5. High reliability and durability

The cycloidal hydraulic motor is highly reliable and durable due to its simple design and the use of high-quality materials. The motor has fewer moving parts, which reduces wear and tear, and it is made of high-strength materials that can withstand high loads and pressures. As a result, the motor has a long service life and requires minimal maintenance.

6. Wide range of options

The cycloidal hydraulic motor is available in a wide range of sizes and configurations, making it suitable for a variety of applications. Depending on the specific needs of the application, users can choose from different displacement options, shaft configurations, mounting options, and more. This flexibility ensures that users can find the right motor for their specific needs.

Various installation flanges, output shafts, oil ports and other installation methods are available to provide great flexibility for the whole machine design. Wide selection to meet equipment speed and torque requirements. One advantage of BMP motors is that they are easy to maintain. The motor is designed to be simple to install and can be easily disassembled and reassembled for maintenance or repair. The comPact design of the motor also makes it easy to install in tight Spaces, which can be an important consideration in many applications.

The OMP BMP hydraulic motor is an efficient, high-quality hydraulic transmission product with the following advantages.

First, the BMP enhanced bearing and gear design makes the BMP series of hydraulic motors suitable for harsher working environments. In addition, the BMP hydraulic motor is compact, lightweight and easy to install, making it widely used in applications where space is limited or weight is limited.

Second, the OMP BMP series hydraulic motor uses a more reliable sealing scheme, so that it has higher accuracy and longer life. The internal seal structure of the OMP BMP hydraulic motor uses multiple leak protection, and adds the application of logarithmic thread sealing technology and other modern sealing technologies. As a result, the OMP BMP series hydraulic motors have greater durability and stability, and can withstand more stringent working conditions and higher working pressures.

Third, OMP BMP series hydraulic motors can be used in a variety of different gear pumps, such as fixed gear pumps, internal gear pumps, external gear pumps and pulley pumps. This means that the OMP BMP series of hydraulic motors can be adapted to a wide range of different situations and needs, including high speed, low speed and high torque applications. In addition, the reliability and adaptability of the OM series hydraulic motors also make them the first choice for manufacturers of heavy machinery and engineering equipment.

Fourth, on a global scale, OMP BMP series hydraulic motors have proven excellent performance in many applications, including Marine, mining, steel, cement, construction and other industries. It has been widely used and praised, proving the reliability and excellent performance of BMP hydraulic motors in a variety of different environments and applications.

In short, OMP BMP series hydraulic motors have many advantages such as high efficiency, high quality, reliability, adaptability and so on, and have become an important product in the hydraulic transmission product market. With the continuous expansion of the application field of OMP BMP series hydraulic motors, their market prospects will be wider in the future.

The fixed rotor pair of the motor adopts the column structure and the inlet seal, which is suitable for high pressure and provides excellent product performance. The motor output shaft is equipped with imported bearings, which are suitable for higher speed and withstand larger axial and radial loads. OMP BMP cycloidal hydraulic motor is a kind of fixed displacement hydraulic motor using cycloidal CAM mechanism. This unique design offers many advantages over other types of hydraulic motors, including high efficiency, low noise levels and good starting capability.

OMP BMP Cycloid Hydraulic Motor Advantages:

The OMP BMP cycloid hydraulic motor offers a range of advantages that make it an ideal choice for various industrial applications. Here are some of the key benefits of using this type of motor:

1. High Efficiency

The OMP BMP cycloid hydraulic motor has high efficiency, which means it can convert the hydraulic energy into mechanical energy with minimal energy loss. This makes it an excellent choice for applications that require high precision and consistent performance.

2. Low Noise Output

The OMP BMP cycloid hydraulic motor has low noise output, which is an important consideration for applications that operate in noise-sensitive environments. The motor's design is optimized to reduce mechanical noise and vibrations, allowing for quiet and smooth operation.

3. Wide Range of Speeds

TheOMP BMP cycloid hydraulic motor offers an excellent speed range that ranges from 10 to 3000 RPM, making it an ideal choice for various applications that require precise control of speed.

4. Compact Size

TheOMP BMP cycloid hydraulic motor has a comPact size, making it easy to install in a variety of different applications. The motor can be mounted in various positions, including horizontal, vertical, or inclined, depending on the needs of the application.

5. High Torque Output

The OMP BMP cycloid hydraulic motor has a high torque output, which is important for applications that require high power and strength. The motor offers a maximum torque of up to 206 Nm, making it an ideal choice for heavy-duty applications.

6. Low Maintenance

The OMP BMP cycloid hydraulic motor requires minimal maintenance, which is an important consideration for applications that require high reliability and uptime. The motor's design is optimized for durability and reliability, meaning that it can operate for extended periods with minimal maintenance.

In conclusion, the OMP BMP orbit hydraulic motor offers a range of advantages that make it an excellent choice for various industrial applications. From high efficiency to low noise output and a wide range of speeds, this type of motor can meet the needs of many different applications. Moreover, its compact size, high torque output, and low maintenance requirements make it a reliable and cost-effective choice for long-term use.

OMP BMP series motors are diverse and can replace products in Asia, Europe, the Americas and other countries and regions. The advantage of connecting the shell drain pipe is that in addition to using the connected motor with lower shell pressure, the motor with the addition of the external shell discharge pipe has normal shell pressure. These advantages are: pollution control - flushing the motor housing, cooling system - the discharged oil allows the motor to dissipate heat and extend the service life of the motor. High efficiency: The OMP BMP Cycloidal Hydraulic Motor has a high volumetric efficiency of up to 98%, which ensures minimal energy loss and maximum power output. Low noise level: The cycloidal cam mechanism of this hydraulic motor minimizes noise and vibration, making it a quiet and smooth operating motor. Good starting capability: The OMP BMP Cycloidal Hydraulic Motor is designed to provide a good starting torque, which is essential for heavy-duty machinery applications.

Hydraulic motors are important components in many industrial machines and processes. Among them, the cycloidal hydraulic motor or the cam ring motor, also known as the "gerotor" motor, has gained popularity for its reliability and efficiency. This type of hydraulic motor is also called a gerotor because it uses a series of rotating gears to produce motion.

The gerotor hydraulic motor uses a circular cam ring with an eccentric orbit that drives a set of rotating gears. The hydraulic fluid is forced into the motor and causes the gears to rotate, which drives the output shaft of the motor. The design of the motor ensures a smooth and continuous motion, making it ideal for applications requiring precision control.

One of the main advantages of gerotor hydraulic motors is their ability to produce high torque at low speeds. This makes them perfect for heavy-duty applications, such as in construction equipment, agricultural machinery, and industrial machinery. They are also more efficient than other hydraulic motors, resulting in lower operating costs over time.

Another benefit of gerotor hydraulic motors is their ease of maintenance. The design of the motor allows for easy disassembly and reassembly, making repairs and replacements straightforward. Additionally, because of their high efficiency, they produce less heat, resulting in longer service life.

Purchasing a gerotor hydraulic motor can bring significant benefits to buyers. Its efficiency, reliability, and ease of maintenance make it an excellent investment for those in industries that rely on hydraulic machinery. Furthermore, with smaller, more comPact designs available, the gerotor motor can even be used in applications where space is limited.

Overall, the cycloidal hydraulic motor or gerotor motor is an excellent choice for those in the market for a reliable and efficient hydraulic motor. Its high torque, low speed, and ease of maintenance make it an attractive option for a wide range of industries.

It is not recommended to use the motor at the highest speed and under the maximum pressure. The maximum inlet pressure is 225bar (peak pressure), do not exceed the rated pressure. Maximum oil return pressure is 225bar (peak pressure), do not exceed the rated pressure. The recommended maximum operating temperature of the system is 82℃. Wide range of displacement options: The BMP Cycloidal Hydraulic Motor is available in a range of displacement options, from 32 cc/rev to 264 cc/rev, to meet different power and speed requirements.

Benefits of the OMP BMP Orbit Hydraulic Motor:

Versatility: The OMP BMP Cycloidal Hydraulic Motor is suitable for use in a wide range of applications, including agriculture, industrial machinery, construction, and more.

Long lifespan: This hydraulic motor is designed with a high-strength alloy housing, which ensures durability and a long lifespan.

Hydraulic motors have a crucial role to play in different industries. From agriculture to marine, construction to transportation, hydraulic motors make it possible to drive machinery and equipment efficiently. And when it comes to high-performance hydraulic motors, OMP BMP orbital hydraulic motors are among the best in the market.

Here are the benefits experienced by using BMP hydraulics:

1. Improved Reliability - The OMP BMP hydraulic motors were designed for durability and could handle challenging operating conditions, including high torque and high-pressure applications. This resulted in fewer breakdowns, and the machines could operate for longer without the need for unscheduled maintenance.

2. Higher Efficiency - The OMP BMP hydraulic motors were more efficient than the previous motors. They could deliver the same performance with less energy, resulting in lower operating costs.

3. Easy Maintenance - The OMP BMP hydraulic motors were designed with ease of maintenance in mind. They had fewer parts that required replacement and could be easily serviced by the maintenance team, resulting in lower maintenance costs and less downtime.

4. Enhanced Performance - The OMP BMP hydraulic motors provided improved performance, resulting in smoother and faster machine operation. This led to increased productivity and higher quality output.

Specification Data

|

Displ. cm3/r |

36 |

50 |

63 |

80 |

100 |

125 |

160 |

200 |

250 |

320 |

400 |

500 |

|

|

Fflow (LPM) |

Continuous |

40 |

38 |

45 |

57 |

57 |

57 |

57 |

57 |

57 |

57 |

57 |

57 |

|

Intermittent |

45 |

45 |

53 |

68 |

68 |

68 |

68 |

68 |

68 |

68 |

68 |

68 |

|

|

Speed (RPM) |

Continuous |

1055 |

698 |

663 |

684 |

580 |

452 |

353 |

284 |

235 |

178 |

145 |

110 |

|

Intermittent |

1250 |

859 |

774 |

842 |

659 |

544 |

364 |

339 |

281 |

210 |

180 |

136 |

|

|

Pressure (bar) |

Continuous |

140 |

124 |

124 |

124 |

124 |

124 |

115 |

110 |

100 |

90 |

90 |

83 |

|

Intermittent |

162 |

138 |

138 |

138 |

138 |

138 |

124 |

124 |

124 |

124 |

110 |

90 |

|

|

Torque (N.m) |

Continuous |

69 |

78 |

99 |

126 |

158 |

194 |

234 |

280 |

318 |

366 |

457 |

527 |

|

Intermittent |

83 |

86 |

110 |

140 |

176 |

216 |

256 |

365 |

394 |

504 |

558 |

570 |

|

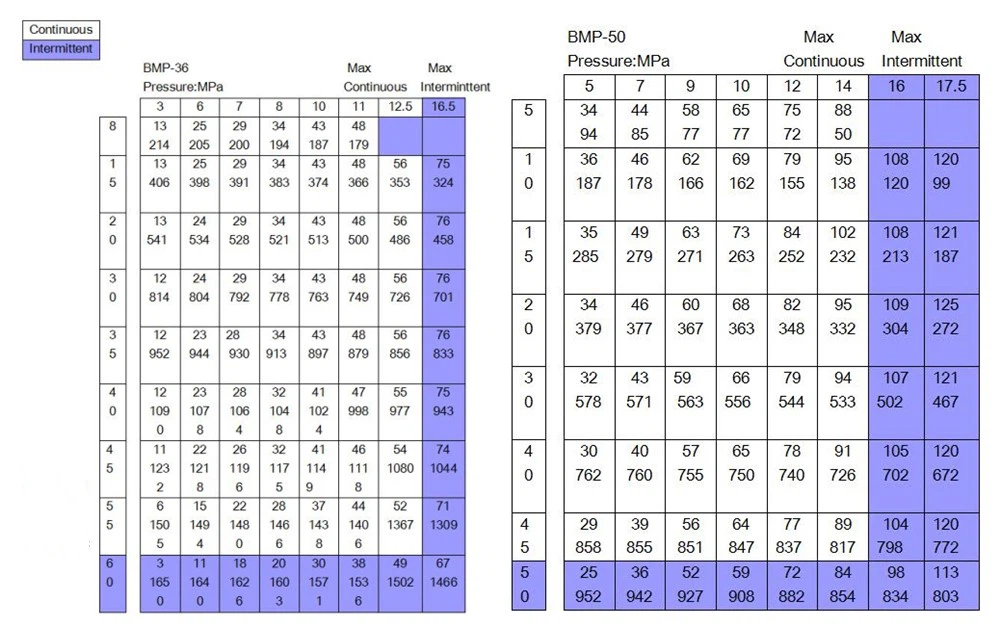

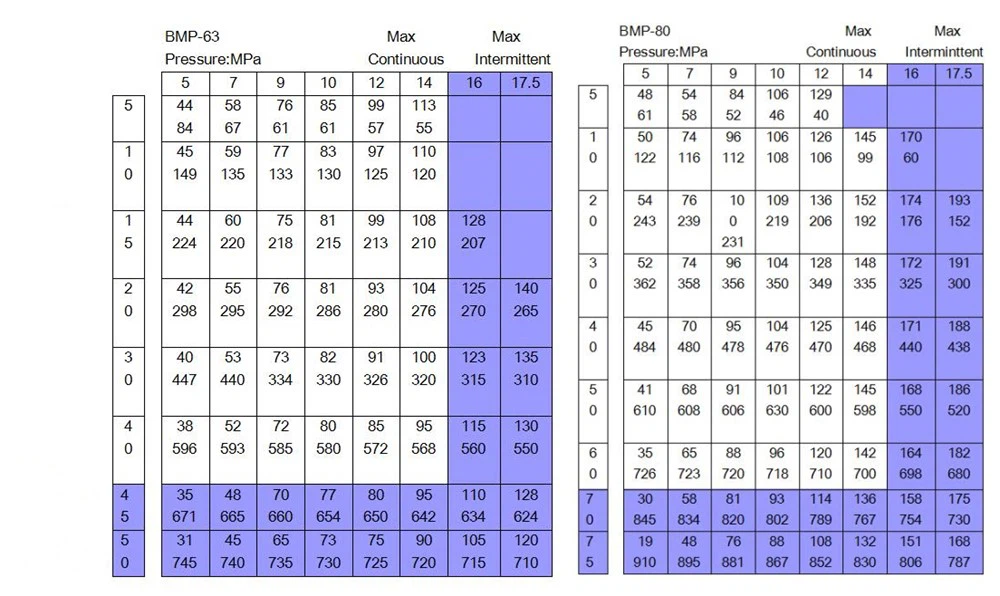

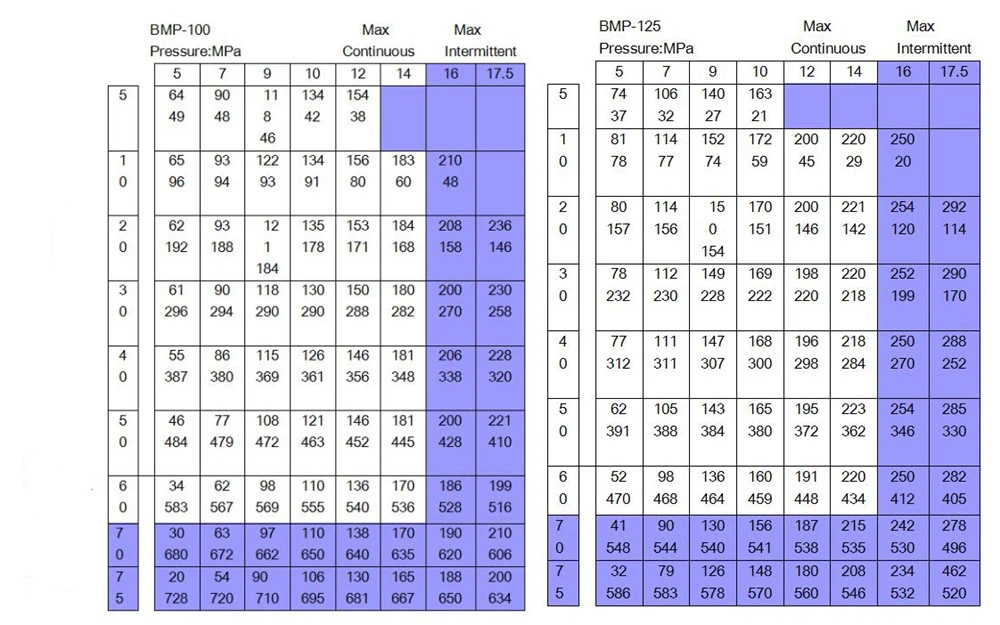

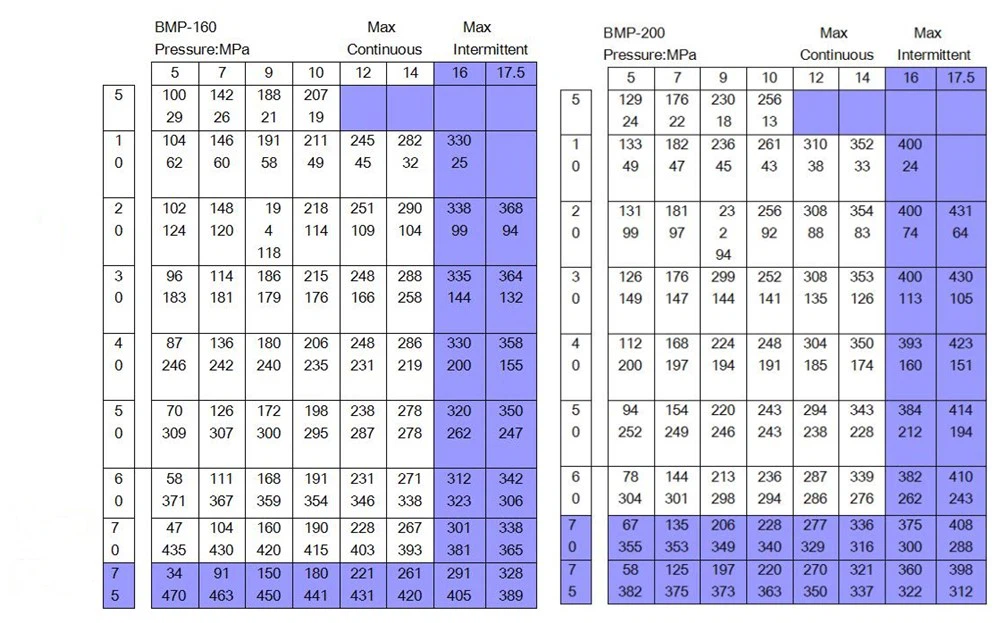

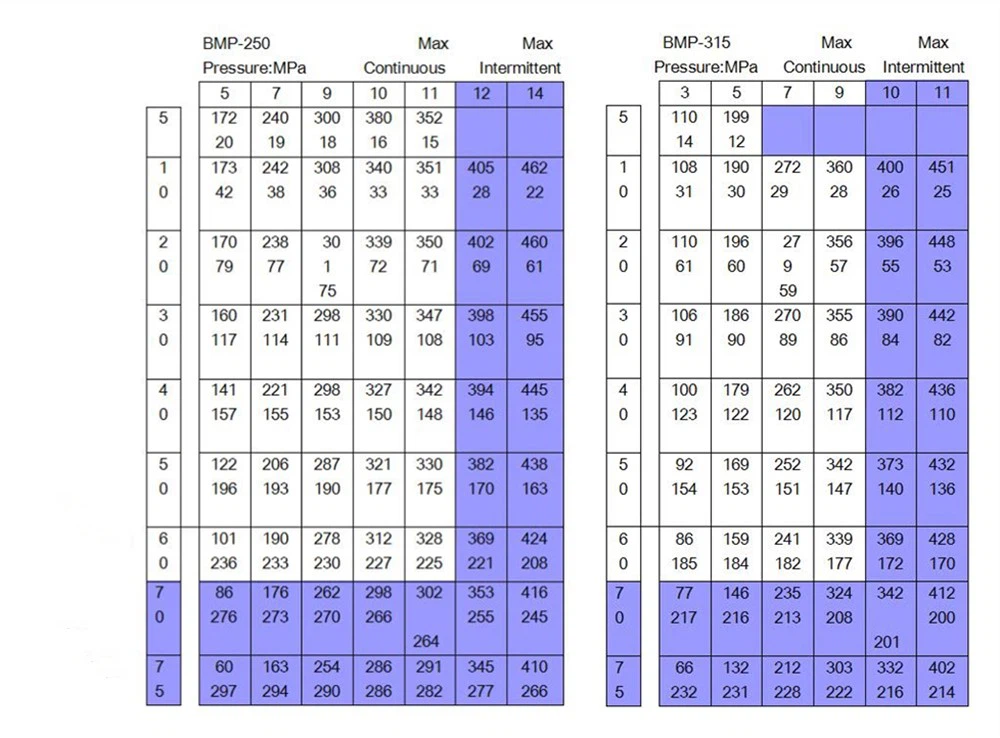

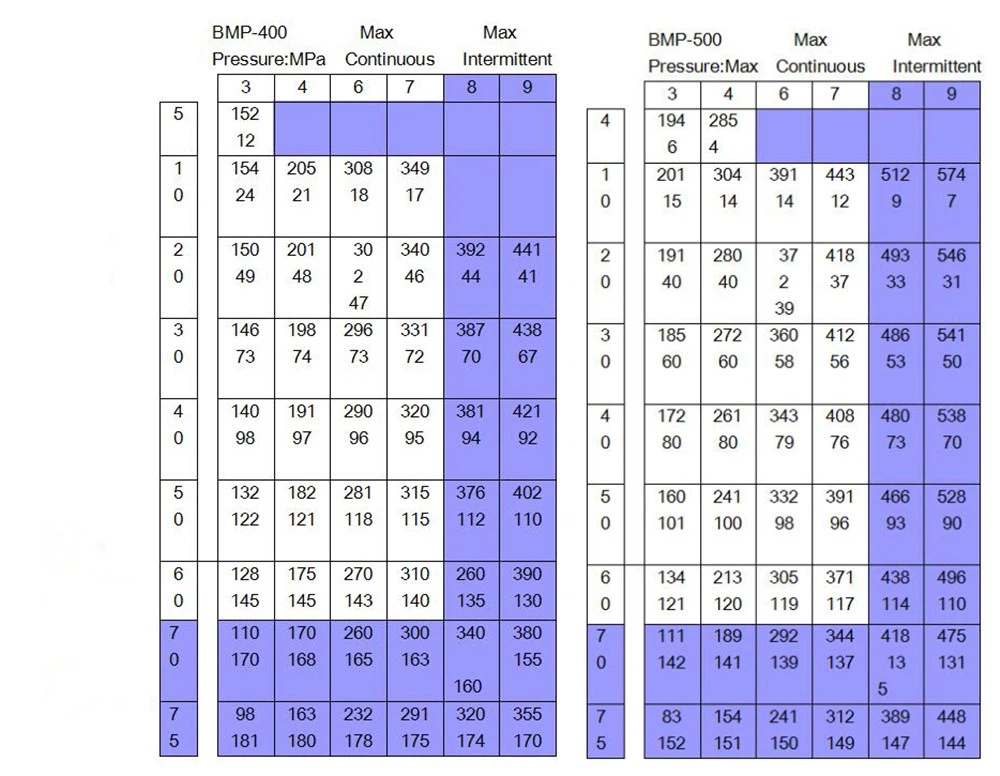

Performance Data

Dimensions of Oil Port

Side Oil Port

Common Flange Form

Dimensions of Shaft

Note: If the shaft is not in the table which you have specific requirements, please contact us.

Direction of rotation

Shaft Side Load Capacity

Order information (GB standard: Select Flowchart)

|

1 |

|

2 |

|

3 |

|

4 |

|

5 |

|

6 |

|

7 |

|

8 |

|

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

||||||

|

Code |

Displ.(CC/r) |

Flange |

Pilot Dia. |

Output Shaft |

Port and Drain Port |

Rotation Direction |

Paint |

||||||

|

BMP |

50 |

F1 |

4-φ11 Bolt Flange Distribution 70x70 |

G1 |

φ80 |

A1 |

Cylindrical Shaft φ25 Parallel key 8x7x32 |

P1 |

(A/B) G1/2 (T) G1/4 |

R |

Standard |

N |

No paint |

|

63 |

|||||||||||||

|

80 |

A2 |

6D-φ25X21X6 Splined shaft |

P2 |

(AB)7/8-14 O-ing (T)7/16-20UNF |

|||||||||

|

100 |

|||||||||||||

|

125 |

F2 |

2 Bolt Flange φ13.5 Dia.Mounting Holes 106.4 Dia.B.C

|

G2 |

φ82.55 |

Q |

Blue |

|||||||

|

160 |

|||||||||||||

|

200 |

A3 |

Cylindrical shaft φ20 Parallel key 6x6x32 |

P3 |

(A/B) 1/2-14NPTF (T) 7/16-20UNF |

|||||||||

|

250 |

F3 |

4-φ11 Bolt rectangle Flange Distribution 105x65 |

A4 |

φ25.325x21.47x6.25 Splined shaft (SAE-6B) |

P4 |

(AB)G1/2 O-ring (T)G1/4 |

|||||||

|

320 |

G3 |

φ85 |

L |

Opposite |

B |

Black |

|||||||

|

400 |

F4 |

4 Bolt Magneto φ13.5 Dia,Mounting Holes 106.4 Dia.B.C |

A5 |

Cylindrical shaft φ25.4 Parallel key 6.35x6.35x32 Shaft head thread M8 |

P5 |

(A/B) M18X1.5 (T) M14X1.5 |

|||||||

|

500 |

A6 |

Cylindrical shaft φ25.4 Parallel key 6.35x6.35x32 Shaft head thread 1/4-20UNC |

P6 |

(A/B)M22X1.5 (T) M14X1.5 |

S |

Silver gray |

|||||||

Note: When the table is used, please fill the code of left rows in dash area and give us, which the code information is consists of construction, displacement, mounting flange. output shaft and ports. If the specification is not in the table or you have specific requirements, please contact us(whatsapp+8615106776651).

FAQ

Maximum Peak pressure at motor inlet port of 225 Bar.

A simultaneous maximum torque and maximum speed NOT recommended.

Continuous Rating - Motor may be maxinum rotate run continuously at these ratings.

Intermittent Operation - 10% of every minute.

Recommended Fluids 一 Premium quality, anti-wear type hydraulic oil. Minimum oil viscosity (at operating temperature) should be the highest of the following: 100 SUS

Recommended Maximum System Operating Temp.一ls 82°C [180°F]

Recommended Filtration 一 per lSO Cleanliness Code, level 18/13

In order to assure best motor life, run motor for approximately one hour at 30% of rated pressure

before application to full load. Be sure motor is filled with fluid prior to any load applications.

Hot Tags: BM1 JH OMP BMP Straight Oil Port Series Orbit Hydraulic Motor with Spool Valve same as Eaton Danfos, China BM1 JH OMP BMP Straight Oil Port Series Orbit Hydraulic Motor with Spool Valve same as Eaton Danfos manufacturers, suppliers, factory, hydraulic piston pump, oz ok series orbit hydraulic motor with spool valve, 2y series orbit hydraulic motor with disc valve, bmrh horizontal oil port series orbit hydraulic motor with spool valve, bm3 series orbit hydraulic motor with spool valve, bm4 series orbit hydraulic motor with spool valve